Technology

A Fundamentally Different Approach.

A Fundamentally Different Approach.

Osmotech’s patented process replaces flammable solvents and high-pressure systems with biodegradable, surfactant-based chemistry operating at ambient conditions.

The result: safer facilities, lower costs, purer output.

From Plant to Pure

The Osmotech process integrates two phases—extraction and purification—into a complete, end-to-end solution. Unlike legacy methods that require separate equipment and facilities for extraction and refinement, Osmotech provides integrated processing from raw biomass to crystalline isolates or purified oils.

Each phase is optimized for different objectives: upstream extraction maximizes yield and selectivity; downstream purification delivers precise crystalline structures or refined oil profiles.

Surfactant-Based Extraction

The Problem

Traditional extraction relies on volatile solvents—ethanol, butane, hexane—that require explosion-proof facilities and leave residual contamination.

The Solution

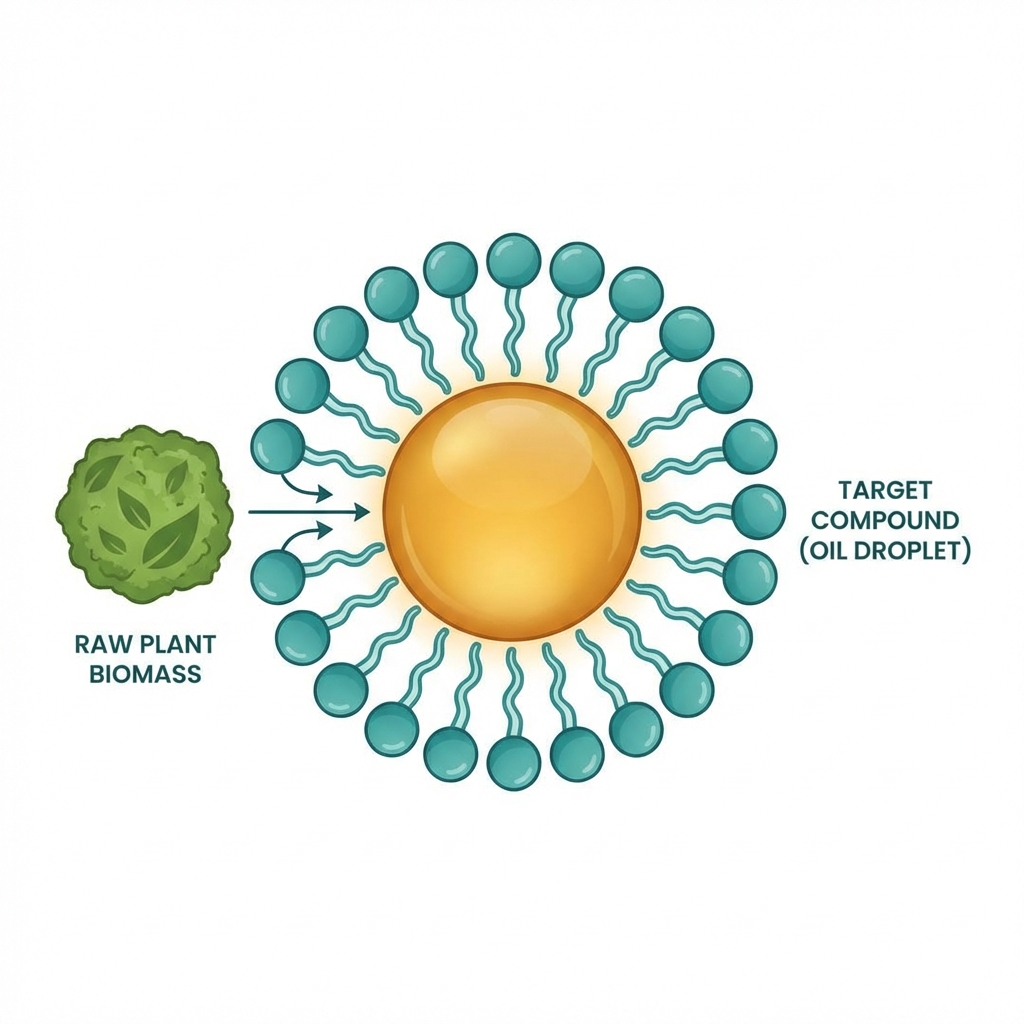

Osmotech’s patented approach uses a biodegradable, surfactant-based process fluid that selectively lifts target compounds through molecular affinity—not brute-force dissolution.

How It Works

- 1

Biomass Introduction

Fresh, wet, or dried plant material enters the system. No grinding to fine particles required.

- 2

Process Fluid Application

Proprietary surfactant formulation penetrates plant structures.

- 3

Selective Compound Lifting

Surfactants encapsulate target molecules based on affinity, leaving undesired compounds behind.

- 4

Mechanical Separation

Hydrated biomass is mechanically processed to recover the extract-laden process fluid.

- 5

Fluid Recovery

Process fluid is separated from crude extract and recycled for subsequent batches.

Fresh Biomass

Process material directly from harvest. No drying required.

Ambient Pressure

No high-pressure vessels. Standard facility requirements.

Zero Solvents

No volatile organic compounds. Automatic ICH Q3C compliance.

Purification & Crystallization

Once target compounds are extracted, the downstream phase transforms crude extract into market-ready products: crystalline isolates at 98%+ purity or refined oils with precise compound profiles.

Crystalline Isolates

Single-compound pharmaceutical-grade crystals

Purified Oils

Targeted compound profiles with unwanted elements removed

Broad Spectrum

Natural compound ratios preserved for entourage applications

The Process

Purification proceeds through controlled crystallization—a technique borrowed from pharmaceutical manufacturing. By precisely managing temperature, saturation, and nucleation conditions, we guide target compounds to form highly ordered crystalline structures while impurities remain in solution.

This isn’t artisanal guesswork. It’s automated, reproducible, and scalable.

Introducing Crystal Clear

Proprietary crystallization control software that transforms manual, operator-dependent processes into automated, reproducible production.

Method-Driven Protocols

JSON-defined protocols enable systematic R&D.

Real-Time Monitoring

Temperature, saturation, and crystal formation tracked continuously.

Hardware Abstraction

Scale seamlessly from pilot to factory floor.

Why Software Matters

In traditional extraction, crystallization is an art—dependent on operator skill, ambient conditions, and batch-to-batch intuition. Crystal Clear transforms it into engineering.

• Configurable method files define every parameter

• Automated execution removes operator variability

• Data logging enables continuous process optimization

• Hardware abstraction means methods transfer seamlessly from R&D to production scale

How Osmotech Compares

Direct comparison against legacy extraction methods.

| Factor | Osmotech | Ethanol | Hydrocarbon (BHO) | Supercritical CO₂ |

|---|---|---|---|---|

| Flammable Solvents | None | Yes | Yes | No |

| C1D1 Facility Req'd | No | Yes | Yes | No |

| High-Pressure Op | No | No | Yes | Yes |

| Fresh Biomass Input | Yes | No | No | No |

| Residual Solvents | None | Yes | Yes | Minimal |

| Pre-Drying Req'd | No | Yes | Yes | Yes |

| CapEx Intensity | Low | Medium | Medium | High |

Inherently Safe

- • Zero explosion or fire risk

- • Non-toxic worker environment

- • Ambient pressure operation

Green Chemistry

- • Biodegradable chemistry

- • Recyclable process fluid

- • Green effluent (NPK fertilizer)

Economic Advantage

- • Up to 50% lower OpEx

- • No C1D1 buildouts

- • Lower insurance costs

Protected Innovation

Osmotech’s technology is protected by a robust intellectual property portfolio.

Primary Patent

Core surfactant-based extraction process protected by issued patent.

Additional IP

4-5 additional patents at various stages covering process refinements.

Our patent portfolio establishes a defensible market position while additional pending applications expand protection.

Ready to Transform Your Extraction?

We’re seeking strategic partners with the resources and infrastructure to bring this technology to commercial scale.